|

Roden

Kit Number 046

An-12 BK-PPS

(Cub C) |

|

Reviewed By Jim Pearsall, #2209 |

|

|

|

MSRP: $44.98 USD The An-12BK PPS was an aircraft with a

different mission. ECM is not much talked about, and the glamour just

isn’t there. Until the opponent’s air defense makes life miserable for

the fighters and bombers. The Cub-C and D carried a large jamming

transmitter, designed to blanket search radars on the other side of the

front and degrade AAA and SAM targeting radar systems. The An-12BK PPS

carries a number of external antennas, plus some interesting vents and

scoops, probably for power units and cooling.

The basic airframe is the An-12 Cub, analogous to the C-130 in size and

mission. 4 turboprops, high wing, short/unpaved field capable, with a fair

cargo capacity. Unlike the C-130, the An-12 is no longer in production,

having been replaced by newer and more capable aircraft types.

I did find a mention of the Cub-C/D in World Airpower Journal Volume

27, Winter 1996. It has (black & white) photos of operational Cub Cs & Ds

and line drawings. The magazine disagrees with Roden on the NATO

designation of the An-12 BK PPS aircraft, calling it Cub-D. According to

WAJ, the Cub-D carried the huge (15 foot / 5 meter) “Sirena” jamming pods

on both sides of the forward fuselage and vertical stabilizer. The

An-12PP, which WAJ calls “Cub-C” did not carry these pods, which would be

the big visual difference between the Cub C and Cub D. Nevertheless, this

is definitely a model of an operational aircraft type. |

|

|

|

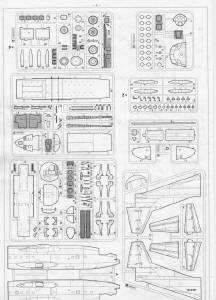

The Model I was prepared for a large box, and

large sprues, having recently built a 1/72 C-130, and was not

disappointed. I find the engineering thought which went into the design

of the trees to be pretty inventive. There are 4 engines, so each engine

assembly is on a single sprue, 4 identical sprues packed in the kit.

These also include half a nose wheel (4 halves = 2 wheels), plus 1 main

gear wheel (4 main wheels). If they use 4 identical molds to make these

sprues, or use the same one 4 times will make a difference on how good

this kit will be in 10 years. If they use this mold 4 times as much as

the others, it will wear out. If they have 4 (or more) of this mold, it

will hold up as well as the fuselage, wings, etc.

Since the ECM pods and antennas are in sets of 2, there are 2 sprues

for them. |

|

|

|

|

Assembly

The instructions start out with multi-lingual cautions

and a paint chart which gives color references for Humbrol, Model Master,

Gunze Sanyo and Lifecolor paints.

From there, it’s the standard pictorial instructions,

with part numbers and sprue references making it fairly easy to locate and

assemble parts. I followed the assembly sequence, and found another

little engineering trick. Since I was spending time on step 8, the

cockpit, the engine front assemblies from step 7 were getting a chance to

rest before assembling the engine back assemblies in step 9. Then

assembling the props (4 blades and 2 spinner parts per prop), the scoops,

the horizontal stabs and the fuselage allowed the engine rear assemblies

to get solid before mating them to the front in step 20.

It was the engine assemblies which convinced me this is

a kit for experienced modelers. I figured out how to use the cowl front

to insure I got the engine front section round, but had more

trouble getting the rear sections to mate securely and still have the

correct circular cross section. No locating pins, not much support, and

flat surfaces meeting which had to be held until everything set up. I

used some putty on the back sections, mostly because I wasn’t able to keep

everything together perfectly. My problem, not Roden’s.

I also had to spend some time getting the mating

surfaces of the front and rear engine sections to meet cleanly. They

didn’t assemble with perfectly flat surfaces, so I squared them up by

rubbing on a sheet of sandpaper on a table. Then I had to be careful

to get the sections to line up radially. There are seam lines on the

bottom of the cowl, which give the alignment, but I would have really

appreciated something with a split ring on one section and a tab on the

other. But how many times have you had to narrow the tab because it

doesn’t line up? Again, patience will have to carry this one through.

I didn’t spruce up the interior beyond painting the

seats and putting the instrument panel decal on. |

|

|

|

The fuselage exterior is quite interesting. I painted

the fuselage first because I knew I’d have to add the windows from the

inside, and didn’t want to mask the clear parts.

This is the step where you add all the scoops, exhaust

ports and antennas to the front section of the fuselage. Because the kit

is a modified Cub, there are no locating marks, etc. The measurements

given on the instruction sheet need to be carefully looked at. I finally

had to copy the drawing at 200% so I could really comprehend it.

After adding all the built-in drag, I inserted the

interior. It fits nicely, and I had no problem getting everything to line

up with the fuselage. I particularly liked the wheel wells built into the

floor board, with alignment tabs to get everything to match. I appreciate

good engineering practice! |

|

|

|

The props are each 6 pieces, so it’s a little finicky

to get the blades all aligned. I pre-painted the prop blades before

assembly, as the section of the blade inside the hub is silver, with the

inner third of the leading edge of each blade also silver. After

assembly, I painted the front of each hub black, and added the yellow

warning tips on each blade.

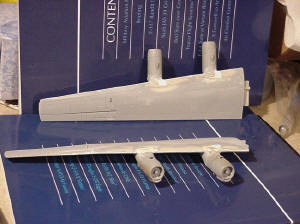

The fuselage continued. I assembled the tail section,

then mated it to the front of the fuselage. I left off the ECM pods

because I know I would have broken the fairly light mounting brackets at

least twice during the fiddling and filling required to get the tail to

mate.

The wing assemblies were well thought out. Each engine

fits in its particular place on the leading edge. The wings have sweep as

well as taper, so each engine fits slightly differently, and the left side

and right side obviously are not interchangeable. I left the props off

the wings, to wait until I had done all the manhandling necessary to get

the wing root joints clean and smooth. |

|

|

|

The wings fit tightly against the fuselage, and the

locating tabs are large and fit the holes in the wing root tightly. It’s

a good thing that the locators actually put the wing in correct alignment

and position. Be a shame to waste good engineering.

I added weight to the fuselage here. Roden suggests

putting a 100 gram weight in the forward radome, just under the navigator

position. Not sure what element they’re suggesting using, but 100 gm of

lead won’t fit inside that radome. I wound up punching out one of the

windows and filling the compartment behind the cockpit with shot and white

glue to get the nose to sit down.

I put on the decals before adding the landing gear, the

nose and cockpit glazing, and the antennas, pods, etc. The large decals

were a handful, as the decal film is thin, and tore if I tried to move it

too much. I had some difficulty figuring out where all the small decals

went. There’s an enlarged drawing showing where they go, but no point of

reference between the enlargement and the standard drawing. You’re left

to figure out what part of the fuselage you’re looking at in the enlarged

illustration.

The landing gear is astonishingly robust, considering

that the actual aircraft uses multiple struts. When reduced to 1/72,

these become too spindly for any one to really be strong enough. But the

design proves itself, and after all the struts are assembled, the gear

supports the model with no rock, shake or twist.

When I assembled the canopy and nose glazing, I found a

big step between the canopy and the fuselage top. File, putty, sand, and

repaint. I ran out of dark grey during this step, and had to buy another

bottle.

Finishing touches. I added the props and the ECM

pods. Finished!!! A final coat of Future, and it’s ready to go to

the next Craig Hewitt Chapter meeting. |

|

|

|

A look back… This was a large project for me, very

ambitious. It would take lots of patience, outstanding craftsmanship, and

a good deal of time to produce an An-12 which would place in an IPMS

Regional. If I were going to do another of these, I would spend some time

making templates from card stock to allow exact placement and alignment of

the add on parts. I would spend less time worrying about panel lines.

The finished model is a real attention getter, even with the single color

paint scheme. This is probably the only kit you’ll ever see of this

particular aircraft type. If you’re interested in Soviet aircraft, or you

have any interest in AEW, this kit is a “must have”. |

|

Information, images, and all

other items placed electronically on this site are the intellectual

property of IPMS/USA ®. |

| |