|

Meteor

Products

Replacement Cowling for Hasegawa 1/48 F6F-5 Hellcat

kit number CEC 48475 |

|

Reviewed By

Charles Landrum, #26328 |

|

|

|

MSRP: $13.99 USD

Review copy provided by Meteor Productions

P.O. Box 3956

Merrifield, VA

22116

Tel: (703) 591-0652

Fax: (703) 591-3996

www.meteorprod.com

The 1/48 Hasegawa F6F kits fit well, are fun to build

and a beautiful representation of the aircraft, but like an encounter

with Cyrano de Bergerac, the nose might distract you. The lower cowling

is misshapen and doesn’t capture the complexity of this area. There is

not much you can do to correct the problem short of creating a new

cowling. The plastic surgeons of Meteor Productions come to the rescue

in their line of Cutting Edge Resin by providing a replacement cowling

for both the –3 and –5 (the difference being two additional cowl flaps

on the underside of the –3 cowling). |

|

|

|

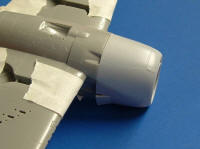

The Cutting Edge cowling is finely molded in their durable

light gray resin. Not only does it provide a more accurate shape, but

also open cowling flaps. The detail is superb. To achieve this level of

detail, the cowling is molded in two pieces. Which means some assembly

is required before mounting it on the plane. Assembly and installation

is pretty intuitive, but the set does not come with any instructions.

I removed the cowling pieces from their mold blocks,

being careful to cut into the block and not cut away some of the

cowling. For much of the removal I was able to accomplish by scoring

with a sharp modeling knife. Although the resin is very durable, I was

still careful around the cowling flap. With the pieces off the blocks

and sanded clean I fit the inner cowl to the main cowling – the fit was

very good and required little effort to snap it in place. Using CA as

filler, I eliminated the seams between the two parts. |

|

|

|

Now I must digress here to point out that I was wrong to

fill the seam between these two parts. By pure happenstance I ran into

Dave Klaus, owner of Meteor Productions, at a Commemorative Air Force

Fly-in. I related my review of the cowling and how filling the seam had

required little effort. It was then that he told me that the F6F has a

prominent seam in each junction and that the inner cowl was slightly

rounded to replicate this detail. Now he tells me! I told him that

instructions pointing this fact out for those of us who are not F6F

experts would be helpful. Dave assumed that anyone who wanted that level

of detail would know of the seams. I think what he forgot is that often

aftermarket products have their own siren song and are bought by those

of us often caught up in the thrill of the hunt! Well my cowling is nice

and smooth up front. With the assembly

completed, I then dry fitted cowl to the model. I was surprised that it

was not a drop in fit. This may be attributed to the curing process, but

I don’t think so. The cowling does not seat properly at the top and the

alignment strip that is supposed to fit into the groove of in the front

of the fuselage is slightly off. The result is that the cowling sits

slightly off center and forms a 1/16inch gap at the top and a step at

the bottom, throwing off the profile as well. The other fit that I

tested was insertion of the engine firewall (with the molded on second

row of cylinders) into cowling. This piece slides all the way forward

the Hasegawa cowling. However, I was unable to move it past the cowl

flaps on the Cutting Edge cowling as the following pictures

demonstrates. |

|

|

|

These problems are minor and easily corrected. With respect

to the overall fit of the cowling, I removed the alignment up on the

upper inner cowling and scraped the mating surface to deepen it. This

worked and the fit of the cowling was much better and the side profile

of the aircraft correct. You will have to sand down the diameter of the

firewall to get it to slide further into the cowling. |

|

|

|

The Cutting Edge Cowling is a nicely patterned component

that is far superior in detail to the Hasegawa part it replaces. Can you

build the kit without it? Sure, but it will enhance the appearance of

the aircraft giving it the more rugged look made famous by the Grumman

“Iron Works”. It is not a drop-in replacement, but only simple modeling

skills are required to achieve a good fit. Highly recommended. |

|

Information, images, and all

other items placed electronically on this site

are the intellectual property of IPMS/USA

®.

|

| |